HLQ/STM SLIDE TABLE AIR CYLINDER ALUMINUM TUBING

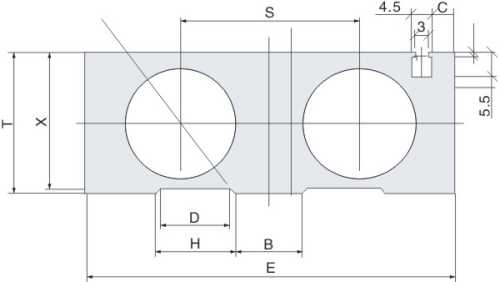

STM Series

| NO | d | E | X | T | D | H | B | C | S |

| 1 | Φ10 | 44 | 16 | 17 | 8 | 10 | 8 | 1.5 | 18 |

| 2 | Φ16 | 59 | 22 | 23 | 11 | 13 | 14 | 1.5 | 30 |

| 3 | Φ20 | 68 | 25 | 26 | 13 | 16 | 17 | 1.5 | 35 |

| 4 | Φ25 | 82 | 31 | 32 | 16 | 18 | 15 | 5 | 40 |

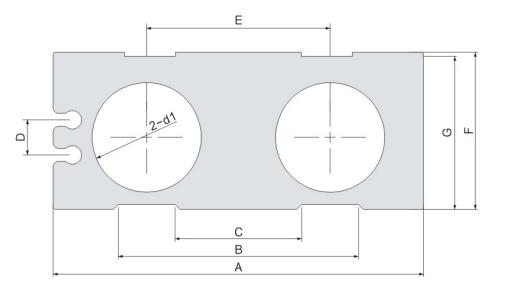

HLQ (φ6-25) Series Slide Table Cylinder Tube

|

NO |

2-d1 |

A |

B |

C |

D |

E |

F |

G |

|

1 |

φ6 |

30.6 |

17.4 |

- |

5.2 |

12 |

11.5 |

10.9 |

|

2 |

φ8 |

40.6 |

24 |

- |

5.4 |

17 |

14.1 |

13.5 |

|

3 |

φ12 |

50.8 |

28 |

12 |

6 |

20 |

19.4 |

18.5 |

|

4 |

φ16 |

60.8 |

38.6 |

15.4 |

6 |

24 |

24.3 |

23.3 |

|

5 |

φ20 |

70.8 |

44 |

20 |

6 |

32 |

29.6 |

28.8 |

|

6 |

φ25 |

84.8 |

55 |

29 |

8 |

42 |

35.8 |

34.9 |

Material of Aluminum Alloy Profile Aluminum pneumatic cylinder tube: aluminum alloy 6063 T5

Our standard Length is 2000mm, if need other length, please freely to inform us.

Anodized surface: Inner tube-15±5μm Outer tube-10±5μm

Accords to design FESTO, SMC, Airtac, Chelic etc.

Accords to the standard ISO 6430 ISO6431 VDMA 24562 ISO15552 etc.

Used for standard cylinder, compact cylinder, mini cylinder, Dual Rod cylinder, Slide cylinder, Slide Table cylinder, Gripper etc. Also for some special cylinders.

Chemical Composition:

|

Chemical Composition |

Mg |

Si |

Fe |

Cu |

Mn |

Cr |

Zn |

Ti |

|

0.81 |

0.41 |

0.23 |

<0.08 |

<0.08 |

<0.04 |

<0.02 |

<0.05 |

Specification:

| Tension Intensity (N/mm2) | Yield Strength (N/mm2) | Ductility (%) | Surface Hardness | Internal Diameter Accuracy | Internal Roughness | Straightness | Thickness Error |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | < 0.6 | 1/1000 | ± 1% |

Torlerance Of Aluminium Alloy Tube:

| TORLERANCE OF ALUMINIUM ALLOY TUBE | ||||||

| Bore Size | TORLERANCE | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: What types of sliding table Pneumatic cylinders are there?

A: Model have MXS and STM pneumatic cylinder

Q2: What is the slide table Pneumatic cylinder?

A: Sliding table Pneumatic Cylinder: Pneumatic sliding table is a linear drive mechanism widely used in the automation industry. It is widely used in the field of machine tools, automation equipment and robots. It is generally driven by compressed air, and the linear movement of the slider is realized through the combined transmission of precision balls and linear slide rails.

Q3: Are there any advantages?

A:

1 Compact integration of sliding table Pneumatic Cylinder work table and Pneumatic Cylinder;

2. The precision Pneumatic Cylinder is suitable for pneumatic sliding tables for precision assembly;

3. High rigidity/high precision, optional adjustable stroke device (0-5mm);

4. The sliding table Pneumatic Cylinder adopts cross ball guide, which has low friction and can realize smooth movement without looseness;

5. The combination of Pneumatic Cylinder and worktable reduces the overall size;

6. Double-Pneumatic Cylinder structure is adopted to obtain twice the output force;

7. Built-in magnetic ring type, magnetic switch can be installed.

8. Pneumatic sliding table pneumatic Pneumatic Cylinder is generally used as the transportation and transportation of precision instruments, and the accuracy is relatively high.

Q4: What is the bore size for MXS?

A: The bore size have Dia 6mm, Dia 8mm, Dia12mm, Dia16mm, Dia20mm