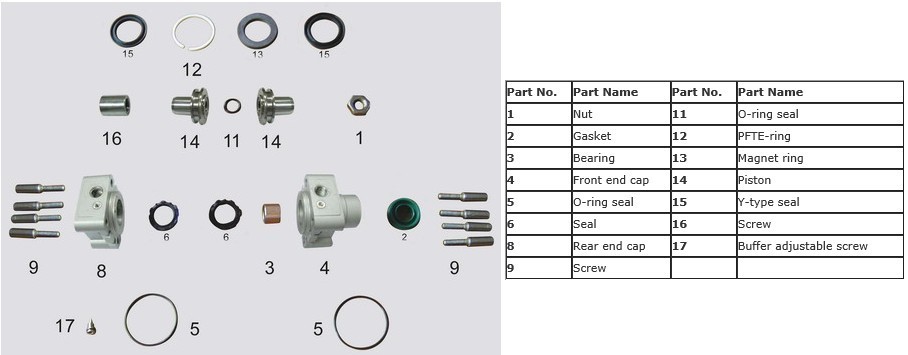

Cylinder structure composition details:

The cylinder is composed of a cylinder tube, end cover (pneumatic cylinder kits), piston, piston rod and seals, etc.

1) Cylinder

The inner diameter of the cylinder represents the output force of the cylinder. The piston should slide smoothly back and forth in the cylinder, and the surface roughness of the inner surface of the cylinder should reach Ra0.8μm.

The SMC and CM2 cylinder pistons adopt a combined sealing ring to achieve two-way sealing, and the piston and the piston rod are connected by pressure riveting, without nuts.

2) End cap

The end cover is provided with intake and exhaust ports, and some are also provided with a buffer mechanism in the end cover. The rod side end cover is equipped with a sealing ring and a dust ring to prevent air leakage from the piston rod and prevent external dust from mixing into the cylinder. The rod side end cover is provided with a guide sleeve to improve the guide accuracy of the cylinder, bear a small amount of lateral load on the piston rod, reduce the amount of bending when the piston rod extends, and extend the service life of the cylinder. The guide sleeve usually uses sintered oil-bearing alloy and forward-inclined copper castings. In the past, malleable cast iron was commonly used for end caps. In order to reduce weight and prevent rust, aluminum alloy die-casting was often used, and brass materials were used for miniature cylinders.

3) Piston

The piston is the pressure part in the cylinder. In order to prevent gas from the left and right cavities of the piston, a piston sealing ring is provided. The wear-resistant ring on the piston can improve the guiding of the cylinder, reduce the wear of the piston seal ring, and reduce the friction resistance. The wear-resistant ring length is made of materials such as polyurethane, polytetrafluoroethylene, and cloth synthetic resin. The width of the piston is determined by the size of the seal ring and the length of the necessary sliding part. If the sliding part is too short, it is easy to cause early wear and seizure. The material of the piston is usually aluminum alloy and cast iron, and the piston of the small cylinder is made of brass.

4) Piston rod

The piston rod is the most important force part in the cylinder. Usually use high-carbon steel, the surface is treated with hard chromium plating, or stainless steel is used to prevent corrosion and improve the wear resistance of the sealing ring.

5) Sealing ring

The part seal at the rotating or reciprocating movement is called the dynamic seal, and the seal of the stationary part is called the static seal.

There are mainly the following methods for connecting the cylinder barrel and the end cover:

Integral type, riveting type, threaded connection type, flange type, tie rod type.

6) When the cylinder is working, the piston must be lubricated by the oil mist in the compressed air. There are also a small number of lubrication-free cylinders.

Post time: Jul-31-2021