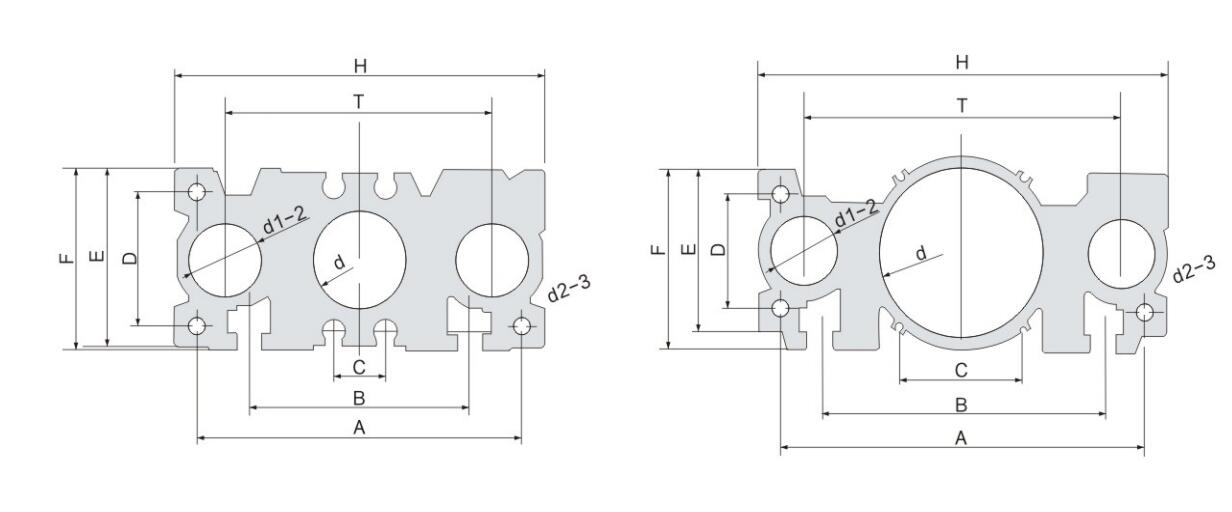

MGP-Z Series Guide Rod China Air Cylinders Tube

MGP-Z Series Drawing

|

NO |

d |

d1-2 |

d2-3 |

A |

B |

C |

D |

E |

F |

H |

|

1 |

Φ12 |

9 |

3.3 |

- |

37 |

8 |

- |

25 |

26 |

58 |

|

2 |

Φ16 |

11 |

3.5 |

56 |

38 |

8.9 |

22 |

29 |

30 |

64 |

|

3 |

Φ20 |

13 |

3.5 |

72 |

44 |

8.9 |

24 |

35 |

36 |

83 |

|

4 |

Φ25 |

17.5 |

4 |

82 |

50 |

11 |

30 |

41 |

42 |

93 |

|

5 |

Φ32 |

21.5 |

5.8 |

98 |

63 |

23.8 |

34 |

47 |

48 |

112 |

|

6 |

Φ4O |

21.5 |

6.8 |

106 |

72 |

25.4 |

40 |

53 |

54 |

120 |

|

7 |

Φ50 |

26.5 |

8.5 |

130 |

92 |

25.4 |

46 |

63 |

64 |

148 |

|

8 |

Φ63 |

26.5 |

8.5 |

142 |

110 |

25.4 |

58 |

77 |

78 |

162 |

|

9 |

Φ80 |

33 |

8 |

180 |

140 |

61 |

54 |

76 |

92 |

202 |

|

10 |

Φ100 |

39 |

11 |

210 |

166 |

73 |

62 |

101 |

112 |

240 |

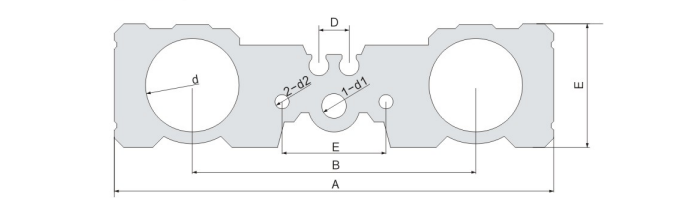

JMGPM (φ12-40) Series Guide Rod Cylinder Tube

|

No |

ID |

d1 |

A |

B |

C |

E |

d1 |

d2 |

|

1 |

φ12 |

φ10 |

58 |

39 |

16 |

17.2 |

φ5 |

φ2.4 |

|

2 |

φ16 |

φ12 |

64 |

42 |

16 |

18.2 |

φ5.2 |

φ2.4 |

|

3 |

φ20 |

φ16 |

83 |

54 |

19 |

22.2 |

φ5.2 |

φ3 |

|

4 |

φ25 |

φ20 |

93 |

60 |

22 |

26.2 |

φ5.2 |

φ3 |

|

5 |

φ32 |

φ25 |

109 |

70 |

23 |

32.2 |

φ5.2 |

φ3 |

|

6 |

φ40 |

φ32 |

120 |

71 |

16.5 |

41.2 |

φ5.2 |

φ3 |

Material of Aluminum Alloy Profile Aluminum pneumatic cylinder tube: aluminum alloy 6063 T5

Our standard Length is 2000mm, if need other length, please freely to inform us.

Anodized surface: Inner tube-15±5μm Outer tube-10±5μm

Accords to design FESTO, SMC, Airtac, Chelic etc.

Accords to the standard ISO 6430 ISO6431 VDMA 24562 ISO15552 etc.

Used for standard cylinder, compact cylinder, mini cylinder, Dual Rod cylinder, Slide cylinder, Slide Table cylinder, Gripper etc. Also for some special cylinders.

Chemical Composition:

|

Chemical Composition |

Mg |

Si |

Fe |

Cu |

Mn |

Cr |

Zn |

Ti |

|

0.81 |

0.41 |

0.23 |

<0.08 |

<0.08 |

<0.04 |

<0.02 |

<0.05 |

Specification:

| Tension Intensity (N/mm2) | Yield Strength (N/mm2) | Ductility (%) | Surface Hardness | Internal Diameter Accuracy | Internal Roughness | Straightness | Thickness Error |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | < 0.6 | 1/1000 | ± 1% |

Torlerance Of Aluminium Alloy Tube:

| TORLERANCE OF ALUMINIUM ALLOY TUBE | ||||||

| Bore Size | TORLERANCE | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: What is the MGPM model?

A:☆ It is SMC standard. The bore size is from Dia12mm to Dia100mm.

☆ Due to technological updates, this magnetic switch slot has changed from square to round.

☆ MGPM series thin guide rod cylinders are compact in structure, small, and do not take up space for installation. They can be installed in relatively small spaces; they can be fixed and installed from the bottom or side of the cylinder with screws, which is convenient for installation; the guide rod is thick and resistant Strong lateral load capacity, can bear larger lateral load, and can be used for pushing out and lifting the workpiece on the conveyor line; the guide rod structure has strong torque resistance.

☆ The MGP guide rod Pneumatic Cylinder is a Pneumatic Cylinder that combines the piston rod and the two guide rods parallel to the piston rod through the end plate. Therefore, the most significant feature of the MGP series guide rod Pneumatic Cylinder is the high non-rotation accuracy, located at ±0.04°~±0.08° , Suitable for machinery that requires high-precision guidance.

Q2: If we buy the MGPM, is it possible with anodizing for Pneumatic Cylinder Tube?

A: This Pneumatic Cylinder is not recommended to be oxidized, because the customer needs to cut it himself and then process it and then perform oxygen treatment after buying it.

Q3: What is the length if we order Pneumatic Aluminum Tube?

A:The length is 2 meter.

Q4: What is the delivery time of Pneumatic Cylinder Barrel?

A: ☆If customized tubes, time need 50-60 working days, but if for the standard tubes, our delivery time is 15-20 working days.