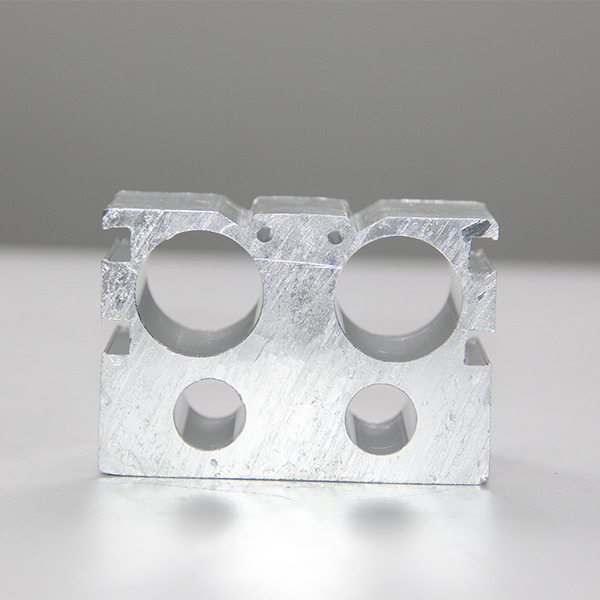

MHZ2/MHLZ AIR GRIPPER SERIES PNEUMATIC CYLINDER TUBE, ALUMINUM ALLOY CYLINDER TUBE

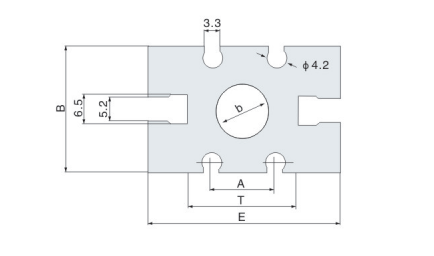

MHZ2 Series Drawing:

|

NO |

d |

E |

T |

A |

B |

b |

|

1 |

Φ10 |

23 |

12.4 |

- |

16.5 |

5.5 |

|

2 |

Φ15 |

30.6 |

19 |

11.6 |

23.6 |

7.5 |

|

3 |

Φ20 |

42 |

24 |

14 |

27.6 |

11.5 |

|

4 |

Φ25 |

52 |

29 |

18 |

33.5 |

13.5 |

|

5 |

Φ32 |

60 |

38.5 |

28.6 |

40 |

13.5 |

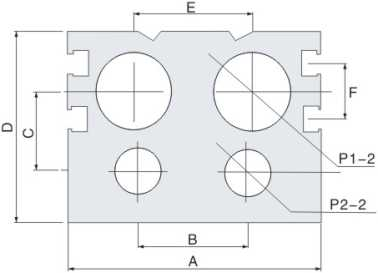

MHL2 Series Drawing:

|

NO |

d |

P1-2 |

P2-2 |

A |

B |

C |

D |

E |

|

1 |

10 |

9.2 |

6.5 |

44.3 |

18.2 |

12.4 |

12.4 |

20 |

|

2 |

16 |

15.2 |

9.5 |

55 |

22.5 |

16.4 |

16.4 |

25 |

|

3 |

20 |

19.2 |

11.5 |

65 |

28.2 |

20 |

20 |

30 |

|

4 |

25 |

24.2 |

13.5 |

76 |

33.3 |

23.4 |

23.4 |

38 |

|

5 |

32 |

31.1 |

15 |

82 |

32.3 |

30 |

30 |

40 |

|

6 |

40 |

39 |

17.4 |

98 |

40.2 |

37 |

37 |

48 |

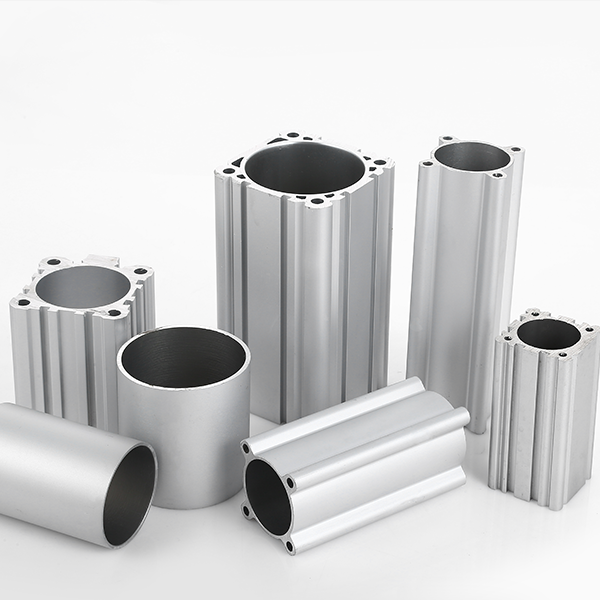

Material of Aluminum Alloy Profile Aluminum pneumatic cylinder tube: aluminum alloy 6063 T5

Our standard Length is 2000mm, if need other length, please freely to inform us.

Anodized surface: Inner tube-15±5μm Outer tube-10±5μm

Accords to design FESTO, SMC, Airtac, Chelic etc.

Accords to the standard ISO 6430 ISO6431 VDMA 24562 ISO15552 etc.

Used for standard cylinder, compact cylinder, mini cylinder, Dual Rod cylinder, Slide cylinder, Slide Table cylinder, Gripper etc. Also for some special cylinders.

Chemical Composition:

|

Chemical Composition |

Mg |

Si |

Fe |

Cu |

Mn |

Cr |

Zn |

Ti |

|

0.81 |

0.41 |

0.23 |

<0.08 |

<0.08 |

<0.04 |

<0.02 |

<0.05 |

Specification:

| Tension Intensity (N/mm2) | Yield Strength (N/mm2) | Ductility (%) | Surface Hardness | Internal Diameter Accuracy | Internal Roughness | Straightness | Thickness Error |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | < 0.6 | 1/1000 | ± 1% |

Torlerance Of Aluminium Alloy Tube:

| TORLERANCE OF ALUMINIUM ALLOY TUBE | ||||||

| Bore Size | TORLERANCE | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: What is the Air Gripper?

A: Air Gripper is also called air finger pneumatic cylinder.

The function of the Air Gripper pneumatic cylinder is to grasp and pick and place objects in the transfer workpiece mechanism, and it is to replace the manual hand to achieve the role of automatic gripping. It is mostly used in automated production lines, manipulators, automatic gripping and other automated mechanical equipment,

With the increasing degree of automation, the pneumatic finger cylinder has become a key part of modern machinery and equipment.

Q2 : Which fields need to use it?

A:Air Gripper cylinders are mainly used in manipulators, automobile/robot industries, molding machines/rubber and plastic machinery/machine tool industries, conveying equipment, packaging machinery, food, medical and chemical industries, office automation and other equipment manufacturing industries.

Q3: What is the model in Air Gripper (pneumatic cylinder aluminium profile)?

A: SMC standard MHZ2 and MHL2 pneumatic cylinder.

Q4: What is the bore size for MHZ2?

A: The bore size have 10mm, 16mm, 20mm, 25mm, 32mm, 40mm.

Q5: What are the characteristics of Air Gripper?

A:

1.All structures are double-acting, can realize two-way grabbing, can automatically center, and have high repeat accuracy.

2.The gripping torque is constant,

3. Non-contact stroke detection switches can be installed on both sides of the Pneumatic Cylinder

4.There are a variety of installation methods and connection methods,

5. Low air consumption

Q6: How about the MHL2 Air Gripper?

A: It is Wide Type Air Gripper MHL2.

1. Long strokes

2. Ideal for holding large-size workpieces that have dimensional variances

3. The double pistons provide a large amount of gripping force.

4. Built-in dust protection mechanism